Over that period, we have gained the knowledge necessary to provide the most effective and well-engineered solutions to our customers.

Our thermal oxidizers can use “street grade” natural gas, raw landfill gas, and/or some of the partially processed high Btu gases derived from the customer’s process as fuel for the burner. In some cases, heat recovery in the form of a heat exchanger is essential to provide heated streams to regenerate the media beds used in the landfill gas processing plants. Heat recovery is also added to the Thermal Oxidizer for preheating the combustion air to the burner to minimize fuel consumption.

-

DRE (Destruction Rate Efficiency) up to 99.99%

-

Control simplicity equals reliability

-

Dual burner means reliable on-line service

-

Refractory selection means long service life

-

Permeate waste stream injected

-

Multi Fuel options

- Controlled Combustion

- Lower emissions

- Heat recovery option (Boiler, Hx)

- Adaptable to stream variations

- Durable, low maintenance

- Fuel options – NG, LFG, waste, high BTU

- High turndown with multiple burners

Contact us by phone or email to discuss your Landfill Gas needs.

CASE HISTORY (PCC Projects 3500 & 3586)

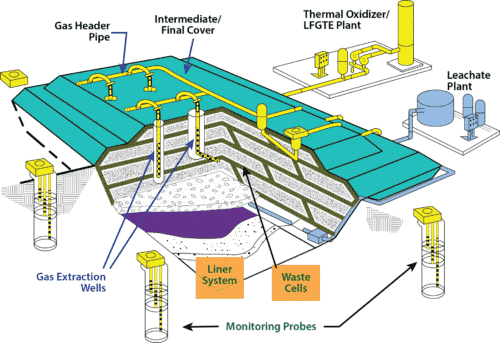

As a supplier of environmental equipment, PCC is especially proud of projects where the environmental impact can be quantified and appreciated. The landfill gas-to-high BTU gas market has become an emerging niche for PCC over the last 10 years as a result of renewable energy efforts. Landfill gas is an easily recovered and desired resource, especially in regions where natural gas is not readily available. Such projects make wise use of otherwise wasted valuable energy, eliminate harmful compounds from the environment, and reduce the dependency upon other fuel sources.

What our customers are saying...

"PCC... The best-kept secret in the industry."

— Rohm & Haas

"PCC works like a well-oiled machine."

— Louisiana Pigments Company

"We would not be where we are today without the engineering knowledge and efforts, quality of construction, professionalism, and cooperation of your first-class organization."

— Montauk Energy Capital

"PCC's commitment to safety and quality allow completion ahead of schedule, under budget, and safely."

—

"PCC's desire to deliver a quality product was apparent throughout all phases of our project, and PCC's overall gas combustion experience resulted in a robust and reliable operating unit."

—

"We are very pleased that it was commissioned five weeks earlier than the contract completion date."

—

"PCC was absolutely on time with delivery of our thermal oxidizer... I was quite impressed. All the units we bought from PCC run flawlessly, even after 10 years. We can't calculate a MTBF, because there have been no failures."

—