Process Combustion Corporation’s (PCC) Dual-BioPhase™ system offers an innovative bio-filtration process that achieves an entirely new level of performance for biological air treatment systems.

What is a PCC Dual-BioPhase™ Bio Oxidation System?

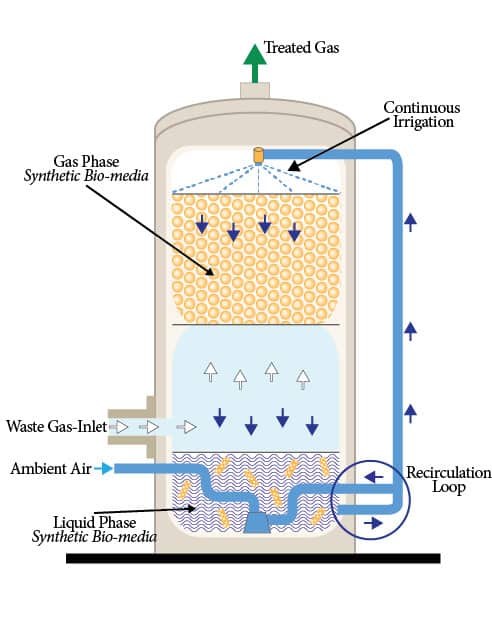

Pollutant compounds that dissolve in water are treated in the water phase while compounds that remain in the air are treated in the gas phase. The Dual-BioPhase™ Technology utilizes synthetic media on which contaminant degrading bacteria are immobilized as biofilm on the surface of the media. As air flows through the bed of media, the contaminant comes in contact with the active biofilm that degrades the pollutant compounds. At the same time, a continuous stream of water flows down through the media to keep the biofilms moist and biologically active.

The system achieves maximum treatment efficiency by adding a nutrient biocatalyst to the water that circulates through the Gas Phase Biological Oxidation Section so that the airborne contaminants are absorbed into the water where they are biodegraded by the aqueous culture.

Thus, with the PCC Dual-BioPhase™ System, contaminant compounds in the air are biodegraded by the active cultures in the liquid phase as well as by the active biofilms on the surface of the synthetic gas phase media.

Advanced VOC and Odor Control Technology

Synthetic Media

Dual-BioPhase™ technology offers important state-of-the-art improvements that translate into tangible performance and economic benefits. Foremost is the unique synthetic media specifically for the Dual-BioPhase™ Bio Oxidation Process. PCC's synthetic media is designed for low-pressure drop and allows ample room for biofilm growth without clogging due to excessive microbial growth. It achieves hydrophilic properties to retain water and support the growth of biofilms on the media surface.

Advantages of PCC Dual-BioPhase™ System vs. Traditional Biofilters

Superior performance of synthetic media allows for:

- Higher gas velocity - reduced size of biofilter

- Shorter gas residence time

- Quicker response to fluctuations in contaminant loading

- Handle higher concentrations of contaminants (VOCs/Odors)

- No fouling/clogging

Dual-BioPhase™ system

A Game‐Changer in Pollution Abatement.

Operation Cost Reduction

Green House Gas Reduction

The Elimination

of NOx

Economics

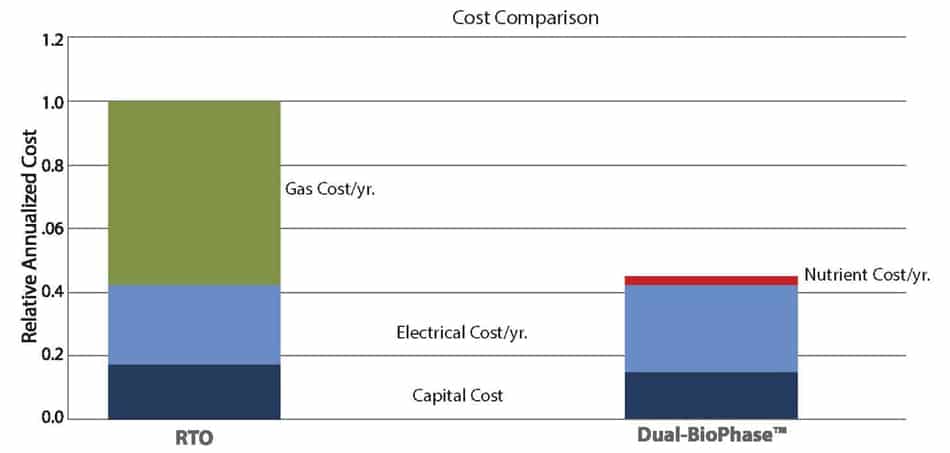

Typically, capital cost is similar, however, the operating cost of a PCC Dual-BioPhase™ system is considerably less than an RTO. Environmental impact is also a significant factor to consider.

Application

High Flow Rate, Low Concentration Contaminated Gas Streams

Bio Oxidation FAQ

Bio Oxidation is a biological process that uses microorganisms to convert HAPs, VOCs, and Odors into harmless by-products of carbon dioxide (CO2) and water (H2O).

Recognizing the limitations associated with traditional bio-filters and other conventional technologies i.e. RTO/RCO, Process Combustion Corporation’s (PCC) Dual-BioPhase™ system offers an innovative bio-filtration process that achieves an entirely new level of performance for biological air treatment systems.

Pollutant compounds that dissolve in water are treated in the water phase, while compounds that remain in air are treated in the gas phase. The Dual-BioPhase™ design utilizes a unique synthetic media on which contaminant degrading microorganisms are immobilized as biofilm on the surface of the media. As air flows through the bed of media, the contaminant comes in contact with the active biofilms thus degrading the pollutant compounds. A continuous flow of water trickles through the media bed to keep the biofilms biologically active and free of biomass build up.

The system achieves maximum treatment efficiency by also adding a biocatalyst nutrient to the circulating water, enhancing absorption of the airborne contaminants into the water where they are biodegraded by suspended culture.

With the PCC Dual-BioPhase™ system, contaminant compounds in the waste gas are biodegraded in the liquid phase of the lower sump, as well as in the gas phase within the upper bed of special synthetic media.

Inlet waste gas temperature is typically in an ambient temperature range of 40°F – 200°F. Temperatures exceeding the design limitation can be adjusted by air mixing, quenching or heat exchanging, as required for each specific application.

- High Flow Rate, Low Concentration

- HAP & VOC abatement – Dual-BioPhase™ technology has a significant cost advantage over RTO (Regenerative Thermal Oxidizer) technology. Typical pollutant concentration range is (25 – 5,000 ppmv). A single Dual-BioPhase™ unit can handle gas flow in excess of 250,000 acfm. Examples of organic compounds include, but are not limited to: aromatic hydrocarbons, sulfur, and nitro containing carbon compounds, alcohols, aldehydes, carbonic acids, ethers, ketones, and some inorganic compounds i.e. ammonia and hydrogen sulfide.

- Odor control – Use Dual-BioPhase™ technology for virtually any odor; especially industrial wastewater where odor and VOC treatment may be required. Typically used where odor concentrations are <50 ppmv.

What our customers are saying...

"PCC... The best-kept secret in the industry."

— Rohm & Haas

"PCC works like a well-oiled machine."

— Louisiana Pigments Company

"We would not be where we are today without the engineering knowledge and efforts, quality of construction, professionalism, and cooperation of your first-class organization."

— Montauk Energy Capital

"PCC's commitment to safety and quality allow completion ahead of schedule, under budget, and safely."

—

"PCC's desire to deliver a quality product was apparent throughout all phases of our project, and PCC's overall gas combustion experience resulted in a robust and reliable operating unit."

—

"We are very pleased that it was commissioned five weeks earlier than the contract completion date."

—

"PCC was absolutely on time with delivery of our thermal oxidizer... I was quite impressed. All the units we bought from PCC run flawlessly, even after 10 years. We can't calculate a MTBF, because there have been no failures."

—