PCC is here to clarify how a thermal oxidizer works.

A well-designed oxidizer will simply exceed 99.9% destruction potency of VOCs.

The typical pollutants treated by oxidizers are Volatile Organic Compounds, commonly referred to as VOCs. VOCs plus Oxygen and heat will result in an oxidizing reaction that breaks down the VOCs to CO2, Water, and more heat.

Major Components of a TO

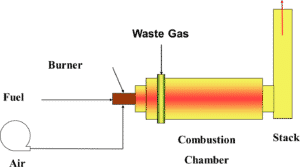

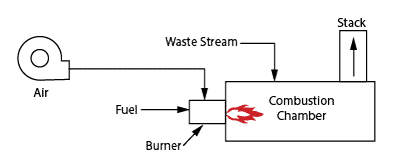

The simplest thermal oxidizer could be a straight TO (aka direct laid-off TO).

Burner

Gas Train

Oxidizer Chamber

Internal High Temperature Insulation

Instrumentation

Control Panel

System fans

Combustion Air Fan

Exhaust Stack

The Process:

A vapor stream, containing the pollutants (VOCs) is commonly sent into the oxidizer chamber by a System Fan. If there is not enough Oxygen present in the vapor stream, additional ambient air will be introduced to complete the reaction.

- Quick Reminder: VOC’s plus Oxygen are required to complete the reaction.

The oxidizer chamber operates at an elevated setpoint temperature ranging from 1450°F to 1650°F+. This temperature is measured by thermocouples in the chamber. The Gas Train and Burner assembly will modulate firing rates to maintain setpoint temperatures based on temperature readings. Maintaining setpoint temperature is critical to ensuring destruction efficiency of VOCs.

- Compliance Note: It is commonly required to data-log this chamber temperature as proof of air permit compliance.

3 Ts

Time, Turbulence, Temperature

Time

The Time component is how the length of time the vapor stream is subjected to elevated chamber temperature.

For a constant flow rate:

Small Oxidizer Chamber = Short Residence Time

Large Oxidizer Chamber = Long Residence Time

Common Residence Time Requirements: .05-1 Seconds

Increased residence times normally equate to higher destruction efficiency of VOCs.

Turbulance

Turbulence performance varies by manufacturer. Turbulence design strives for mixing and distribution outcomes that maximize performance. As you recall, VOCs plus Oxygen and Heat yields the complete reaction. Therefore, it is important that all three mix well and as uniformly as possible.

If there are cold spots / dead spots in an oxidizer or the oxygen component isn’t mixed well with the VOCs then the reaction may not be as complete and less destruction efficiency may result. To ensure good mixing (Turbulence) some designs call for a certain length to diameter ratio for the oxidizer chamber. Other designs introduce the vapor stream tangentially into the chamber for a spin effect. Some designs have internal choke points and others have a profile plate to bring the vapors close to the flame. There are many ways to promote even mixing and heat distribution to satisfy the Turbulence requirement.

Temperature

Chamber Setpoint Temperature at 1500°F = 1500°F hot vapor gases exiting the stack to the atmosphere.

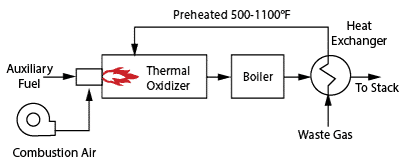

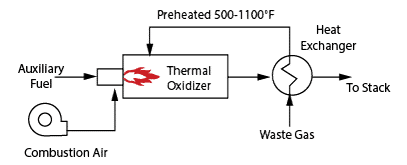

Some may consider the 1500°F hot gases exiting the stack, as a lot of energy being wasted and if this energy could be used to make steam or for preheat. This concept of energy recovery and reuse creates oxidizer categories like Recuperative Thermal Oxidizer, RTOs, and more. Recovery systems add additional features to improve energy efficiency. Regardless of energy usage, the primary goal of any oxidizer is the destruction of air pollutants, namely VOCs.

The vapor stream that's directed into the new combustion chamber, experiences the 3 Ts within the chamber, then exits towards the exhaust stack. The exhaust stack has samples ports for compliance testing and periodic sampling to substantiate destruction of the VOCs and since this is often a straightforward straight thermal oxidizer, there's no heat recovery.

Conclusion: How do Thermal Oxidizers work?

The theory of operation of a straight thermal oxidizer is simple. A vapor stream containing VOC pollutants is directed to an oxidizer chamber, that has been well designed with the three Ts in mind: Time, Turbulence, and Temperature. The oxidizer chamber is controlled to maintain an elevated setpoint temperature by modulating the firing rate of the Gas Train and Burner assembly. In the hot chamber, the VOCs will react with Oxygen and break down to less harmful components, CO2 and Water. Finally, the vapor stream discharges through the exhaust stack with the VOCs destroyed to meet the air permit requirements.