PCC’s high intensity, multifuel, low NOx burners, and combustors have set the standard for quality and reliability. While available in a wide range of standard sizes, we can custom engineer them to meet your unique needs. If desired, we can offer turnkey construction and project management to handle the job from start to finish.

High Intensity

Multifuel

Low NOx

Low NOx

As low as .02 lbs per million available

Heavy Liquids

Light Liquids

Burn

Gases

Any Combination

Ultra Low NOx Emissions

Burner designs use a variety of techniques to reduce flame temperature thus dramatically reducing NOx.

Low CO Emissions

The burner’s refractory baffles allow for strong stabilization and mixing, substantially reducing possible CO generation even at low O2 levels.

Allows for a turndown of up to 10:1 for gaseous fuels and 4:1 for liquids.

Quality - Reliability

Each burner is custom-designed and manufactured under strict quality control guidelines. The core of the ruggedly designed burner is the refractory baffle, which shields the burner internals from furnace radiation, allowing long life and stable operation over wide temperature and air/fuel ratio ranges.

Standard Burner

The standard burner accepts preheated combustion air up to 575°F. Higher temperatures, up to 850°F, can be used on burners with a heat resistant steel plenum. If required for safety or economy, adding an insulating inner lining to the plenum is an option. The standard burner requires a suitable high temperature space to contain the whole flame initiated by the burner.

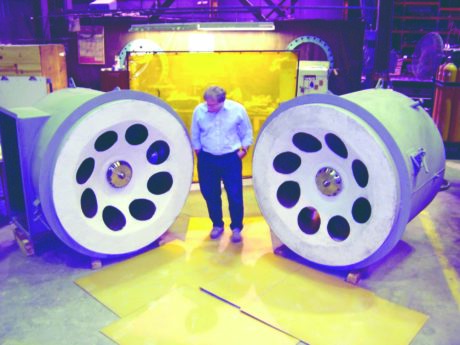

OGH Combustor

This combustor combines PCC’s burner with a short refractory-lined air-cooled fire tube to mix fuel and air, initiate a stable flame front and provide a high-temperature environment where combustion air is preheated and mixed. This design provides an atmosphere where combustion continues to promote the relatively short and well-defined flame, which exits from the combustor. Limited space is required for completion of combustion.

Combustor designs are available for various heat release and preheated air.

Contact PCC to discuss your project and learn about our solutions.