Thermal Oxidizers

Contact Form

Thermal oxidizers reduce air pollution emissions from a variety of industrial processes.

Using the principle of “thermal oxidation,” a combustion process, the contaminants within the polluted exhaust gas react with oxygen in a temperature controlled environment. The chemical oxidation reaction destroys the contaminants in the polluted exhaust gas before discharging it back into the atmosphere. What is released is an innocuous emission of CO2, water vapor, and heat.

Thermal Oxidizers FAQ

What are thermal oxidizers?

Thermal oxidizers reduce air pollution emissions from a variety of industrial processes.

Using the principle of “thermal oxidation,” a combustion process, the contaminants within the polluted exhaust gas react with oxygen in a temperature controlled environment. The chemical oxidation reaction destroys the contaminants in the polluted exhaust gas before discharging it back into the atmosphere. What is released is an innocuous emission of CO2, water vapor, and heat.

PCC Thermal Oxidizers

PCC thermal oxidizers operate on the principle mentioned above, which is thermally promoting an oxidation reaction between the pollutant compound in the exhaust gas and the available oxygen. We supply two types of the Thermal Oxidizers: direct fired (afterburner) and recuperative thermal oxidizers.

1. Direct Fired Thermal Oxidizer – The simplest type of thermal oxidizer, it does not include any type of heat recovery system to recover a portion of the waste heat generated by the combustion process. A direct fired thermal oxidizer system typically includes:

- Burner

- Combustion chamber

- Blower

- Air/fuel train

- Instrumentation and controls

- Exhaust stack

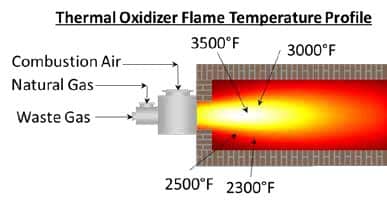

Typically less expensive than other types of thermal oxidizers, direct fired thermal oxidizers will incur higher operating cost (fuel use) for waste streams that are endothermic (see Figure 1).

Figure 1 – Direct Fired Thermal Oxidizer (Afterburner)

2. Recuperative Thermal Oxidizer (Afterburner) – Basically, this system is a direct fired thermal oxidizer with heat recovery added at the discharge end of the combustion chamber. Recuperative thermal oxidizersincorporate downstream heat recovery equipment, such as gas- to-gas heat exchangers, waste heat recovery boilers, gas to liquid heat exchangers, etc… to maximize the thermal oxidizer system overall efficiency.

Downstream heat recovery equipment uses the available heat produced within the thermal oxidizer combustion chamber to reduce auxiliary fuel consumption, produce steam, heat a process air stream, or heat a liquid stream. A recuperative thermal oxidizer system can have a single heat recovery device (Figure 2), or multiple heat recovery devices (Figure 3).

Figure 2 – Single Heat Recovery

Figure 3 – Multiple Heat Recovery

In addition to the recuperative thermal oxidizer systems shown above, a recuperative thermal oxidizer can incorporate:

- Combustion air preheat to conserve fuel

- Other heat recover equipment such as a hot oil heater, hot water economizer, or asphalt heater

Recuperative thermal oxidizers can treat multiple gaseous and liquid waste streams that are endothermic and/or exothermic.

Need more information? Request it here or Request a Quote

How are thermal applications custom designed and proven?

Our core engineering staff is experienced in process engineering, material selection, refractory design, structural design, and controls and instrumentation. With degrees in various engineering disciplines, our Professional Engineers (P.E.) are also registered in several states.

We’ve custom designed more than 1,000 systems for Fortune 500 companies of all sizes– and we have an excellent track record for performance and reliability. Here are some of our typical applications.

| Typical Wastes |

|---|

| Acrylonitrile |

| Terephthalic Aced |

| Butanediol |

| Mercaptaines |

| Low BTU Gases |

| VOC’s |

| Waste Oils |

| Butyl Chloride |

| Phosphine |

| Hydrogen Cyanide |

| Toluene |

| Benzene |

| Halogenated Hydrocarbons |

| Trichloropropene |

| Maleic Anhydride |

| Dibutyl Phthalate |

| Trifluoroacetic Acid |

| Chloridated Hydrocarbons |

| We serve industries including: | |

|---|---|

| Chemical | Converting |

| Petrochemical | Metals |

| Refining | Food |

| Automobile | Wood products |

| Pharmaceutical | Sulfur |

| Manufacturing | Carbon |

| Textile | Pulp and paper |

| Rubber | Landfill & Digester Gas |

Why do major American automobile manufacturers trust PCC’s dynamometer engine testing?

Process Combustion Corporation’s recuperative thermal oxidizer system has been selected by automotive engineers, consulting engineers, environmental engineers, and engine testing personnel as the most reliable emission control technology for engine dynamometer testing applications.

Why us?

PCC supplies most major American automobile manufacturers with state-of-the-art recuperative thermal oxidizer and non-recuperative thermal oxidizer systems. Our pollution control equipment is not only designed to reduce emissions from engine testing facilities, but also to meet or exceed all Maximum Achievable Control Technology (MACT) standards for dynamometer engine testing applications.

Put to the test.

As part of the automotive industry’s constant commitment to product develop and product reliability, all automotive manufacturers conduct rigorous engine testing, engine part testing, transmission testing, and other tests, as part of their research and development programs. Engine testing is generally conducted using engine dynamometer test cells installed in the automotive manufacturer’s engine production plant.

The engine dynamometer test cell (sometimes called “dynos”) is a highly instrumented and tightly controlled room in which the engine is directly coupled to the dynamometer. The sophisticated dynamometer allows the automotive engineer to simulate “real world” engine operating scenarios along with engine durability tests, engine performance tests, combustion analysis tests, engine emission tests, and other tests all aim at improving engine performance. As one might expect, engine testing generates exhaust emissions, which can contain high levels of carbon monoxide (CO), unburned hydrocarbons (UHC), nitrogen oxides (NOx), hydrogen (H2), sulfur dioxide (SO2), and carbon particulate. Under the new MACT standards, new or reconstructed engine test cells/engine test stands that test internal combustion engines with a rated power of ≥ 25 hp must limit emissions of carbon monoxide and unburned hydrocarbons: Many state implementation plans (SIP) require NOx emission limits as well.

We aren’t kidding when we say that most automotive manufacturers have selected PCC’s recuperative thermal oxidizer system to address these emission control issues. Designed specifically for the uniqueness of every dynamometer engine testing application, PCC’s recuperative thermal oxidizer system offers advantages for every engine testing application:

-

- Custom designed specifically for each engine test application

- Designed for idle and wide open throttle (WOT) engine conditions

- Proper engine exhaust collection header design that does NOT impact engine testing in any adverse way

- Fuel efficient design features which minimize operating cost

- Robust and reliable equipment reduces maintenance and repair costs

- Combustion chamber design features ensure high destruction efficiency and environmental compliance

- User-friendly PLC-based control system with operator interface screen

- Compact equipment arrangements reduce plot space requirements

- EXACT application designs are field tested and proven

- Maximum safeties ensure safe unattended operation

What is the vital role of thermal oxidizers?

Thermal oxidizers have played a vital role in Emissions Control Permitting since the Clean Air Act Amendments of 1990. By reducing the levels of pollutants that are released to the atmosphere thermal oxidizers are effective in the destruction and removal of more than 80% of the 189 specified Hazardous Air Pollutants under the CAA.

Along with identifying this list of 189 toxic air pollutants, the Clean Air Act Amendments (CAA) of 1990 established programs that set limits on how much of a pollutant can be in the air anywhere in the United States. In order to achieve the pollution limits, the CAA created an Emissions Control Permitting program for larger stationary sources.

What is a “stationary source”?

According to the Unites States EPA, a “stationary source” is “any building, structure, facility, or installation, which emits or may emit any air pollutant.”

Clean Air Act, Title 1, Section 111, Subsection 3

What does the Clean Air Act mean for business owners?

Under the program, owners of sources are required to obtain an Emissions Control Permit from the state in which it resides.

The Emissions Control Permitting process forces owners to:

- Monitor and measure the amount of pollutants that are released from each source

- Provide information about which pollutants and the quantity of pollutants that may be released

- Reveal steps taken to reduce the amount of pollution

Visit the US EPA website at www.epa.gov for more information about Emissions Control Permitting.

What is the important issue of VOC destruction and removal?

Many industrial processes emit volatile organic compounds (VOC’s). Due to the role of this compound in air pollution, VOC destruction and removal is a prominent issue in our society.

Along with identifying this list of 189 toxic air pollutants, the Clean Air Act Amendments (CAA) of 1990 established programs that set limits on how much of a pollutant can be in the air anywhere in the United States. In order to achieve the pollution limits, the CAA created an Emissions Control Permitting program for larger stationary sources.

VOC defined.

A volatile organic compound (VOC) consists of carbon (excluding carbon monoxide), carbon dioxide, carbonic acid, metallic carbides or carbonates, and ammonium carbonate, which participates in atmospheric photochemical reactions.

In response to this growing concern, the Clean Air Act Amendments (CAA) of 1990 were passed. These amendments changed the focus of air pollution from a set of six “priority pollutants” to the control of VOC’s. The CAA is intended to reduce the emissions of VOC’s by 70-90%. Subsequent legislation has also been passed to further reduce the emissions of VOC’s to the atmosphere.

VOC destruction and removal rates greater than 99.99%.

Since the inception of the 1990 Clean Air Act, thermal oxidation systems have continued to play one of the most important roles in VOC destruction and removal, due to its ability to destroy the VOC’s in a one-step process while producing innocuous by-products.

A properly designed thermal oxidizer system can achieve VOC destruction and removal rates greater than 99.99%.

Other advantages of thermal oxidation include:

- Ease of operation and control

- Ability to be altered for process variations

- Continuous process

- Elimination of by-product disposal

- Number of process components

- Ability to be applied to more than 80% of the CAA Air Toxics

Industries for which thermal oxidizers have been used for VOC destruction and removal include, but are not limited to:

- Petrochemical

- Man-made Fibers

- Petroleum

- Pulp & Paper

- Automotive

- Energy

- General Manufacturing

- Pharmaceuticals

- Animal Rendering

Email us or call at 1.412.655.0955 to see how we can help you achieve your VOC destruction and removal goals.

How do waste heat boilers recover energy and conserve fuel?

PCC specializes in designing and engineering fully integrated thermal oxidizer systems. Many times that includes downstream heat recovery equipment along with additional downstream pollution control equipment, as required for the specific pollution control application.

PCC recuperative thermal oxidizers integrate a waste heat boiler into the complete system. If the application is such that the end user needs a thermal oxidizer system for pollution control and also has a need for steam, adding a waste heat boiler to the thermal oxidizer system is a highly effective way to recover energy that would otherwise be discharged to atmosphere. Typically, the waste heat boiler is located after the thermal oxidizer combustion chamber. The primary function of the waste heat boiler is to utilize the thermal oxidizer hot products of combustion to generate steam, which can be utilized within the end users production process, within their building facilities, within the thermal oxidizer system itself, or even sold to neighboring facilities that need steam. All of these options result in a financial benefit for the end user, because their steam requirements are satisfied using the waste heat boiler without the added capital and operating expense associated with a separate direct fired boiler system.

A waste heat boiler recovers additional energy recovery and fuel conservation by:

- Adding a boiler feed water economizer to the waste heat boiler. The boiler feed water economizer is basically a gas-liquid heat exchanger located after the boiler evaporator section. The economizer also uses a portion of the energy contained in the thermal oxidizer combustion gases (after the waste heat boiler) to preheat the boiler feed water before it enters the boiler evaporator section.

- Using excess steam produced by the waste heat boiler to preheat a waste gas or combustion air stream coming to the thermal oxidizer system. A waste gas or combustion air steam pre-heater uses the excess steam from the waste heat boiler to preheat these streams prior to entering the thermal oxidizer. This reduces the thermal oxidizer auxiliary fuel use and therefore reduces the overall system operating costs.

Typical waste heat boilers used on thermal oxidizer applications include firetube boilers and watertube boilers.

Firetube boilers – Generally for smaller applications, where the thermal oxidizer system heat release is below 20 MM Btu/hr and when high pressure steam is not required.

Watertube boiler – More suitable for larger applications with high pressure steam requirements.

Countless configurations and the expertise to recommend them.

So many options… our experts will help you chose the most effective one.

There are many different process configurations available for integrating a waste heat boiler into a recuperative thermal oxidizer system. PCC has supplied recuperative thermal oxidizer systems with a waste heat boiler as the primary heat recovery device followed by multiple heat recovery devices such as combustion air and waste gas pre-heaters.

Careful analysis of emission and steam requirements, process operating conditions, and operating cost objectives is our expertise. We’re here to help.

Does PCC supply and sell thermal oxidizer anywhere in the world?

PCC sells and installs thermal oxidizers worldwide in North and South America, China, Taiwan, Korea, Malaysia, Thailand, India, Africa, Australia, Middle East, Kazakhstan, and many other European countries. This global experience gives us valuable thermal oxidizer sales and project execution expertise to successfully handle any thermal oxidizer project regardless of installation location and culture. We support our thermal oxidizer sales channels with a highly talented, experienced, and professional in-house sales team and experienced sales representatives and agents located throughout North and South America and other countries such as China, Malaysia, and Thailand.

PCC’s thermal oxidizer sales team and project engineering team offer unique benefits and added services:

- Custom designed systems

- Proven thermal oxidizer experience

- Global thermal oxidizer sales and project execution

- Financial strength through corporate ownership

- Installation, commissioning, and operator training support

- Spare parts and regular maintenance service

- Customer-oriented culture

Please email or call us directly at (412) 655-0955 for more information about PCC and how we can help design your pollution control solution.

How will the thermal oxidizer experience work for my company?

PCC’s broad range of thermal oxidizer experience includes industrial, chemical, petrochemical, refinery, automotive, pharmaceutical, food, textile, mineral, wood products, carbon products, paper applications, and tobacco. This wide spectrum of industrial applications enhances our thermal oxidizer experience and expertise by exposing PCC to a wide range of waste streams that contain components such as Acrylonitrile, Hydrogen Cyanide, Chlorinated Hydrocarbons, Halogenated Hydrocarbons, Phospine, Acrylic Acid, Ammonia, Mercaptanes, Carbon Monoxide, and many others.

Active participation in a diverse range of industrial applications coupled with close customer partnerships has given PCC extensive combustion and thermal oxidizer experience. We are perfectly prepared to custom design a pollution control solution that supports your production needs and objectives.

Along with hundreds of engineered projects to meet your unique requirements, our thermal oxidizer experience includes:

- Advanced low emission systems

- Multi-staged low NOx incineration

- Low BTU gas burning

- Thermal destruction of nitrogen bearing compounds

- Waste heat recovery

PCC’s broad range of thermal oxidizer experience makes us the market leader in the design and supply of advanced, custom designed thermal oxidation systems for the destruction of industrial waste gases and liquids.

Whether the application requires a standard “off the shelf” thermal oxidizer or a custom designed fully integrated thermal oxidation system as shown below, PCC performs for you.

Complete system integration is our specialty.

PCC’s team of application and design engineers understands the need for integration of equipment and accessories from you (the customer’s) perspective.

We have custom designed systems for many Fortune 500 companies ranging from $5,000 to more than $11 million dollars. Our professionals bring a wide range of global experience in application/process design, project engineering, project management, material selection, procurement, fabrication, inspection, transportation, installation, commissioning, and start-up.

Contact PCC at (412) 655-0955 to learn how our thermal oxidizer experience can benefit your project.

What is thermal oxidizer design and how do you choose the right supplier?

Virtually every industrial manufacturing process results in waste products— cause for concern in today’s environment. Thermal oxidation has proven through the years to be an effective and safe method for the disposal of a wide variety of industrial wastes if proper thermal oxidizer design practices are followed.

Thermal oxidizer design can be relatively straightforward or complex depending on the application, waste characteristics, and the air permit emission requirements. Most thermal oxidizer designs incorporate similar design principles to ensure that the desired oxidation reaction occurs and the waste stream contaminants are reduced to the levels necessary to achieve emission compliance.

How do you go about developing a thermal oxidizer design?

Step 1

An important first step in any successful thermal oxidizer design process is providing the thermal oxidizer supplier with clear and specific process design “inputs” and “outputs.”

Thermal oxidation process defined.

Thermal oxidation is the effective employment of a process that provides thorough mixing of an organic substance with sufficient oxygen, at a high enough temperature, for a sufficient time, to cause the organics to oxidize to the desired degree of completion.

Here are typical thermal oxidizer design inputs and outputs.

Typical Design Inputs:

- Upstream process operating conditions (batch or continuous process)

- Full range of process operating conditions (Max., Min., Norm., Start-up, Upset, Design, etc.)

- Waste stream design parameters (flows, pressures, and temperatures)

- Waste stream composition and variability

- Available utilities, site conditions, and physical equipment constraints

Typical Design Outputs:

- Air emission limits (CO, NOx, VOC, SOx, HCl, PM, etc.)

- Performance requirements (fuel consumption, reliability, noise, etc.)

Step 2

Begin thermal oxidizer design process.

Once these parameters are defined, the thermal oxidizer design process can begin. A basic thermal oxidizer system consists of a refractory lined vessel known as the thermal oxidizer, a burner, stack, and combustion controls.

Design inputs – Process application upstream of the thermal oxidizer and the corresponding waste stream or streams that need to be treated by the thermal oxidizer.

Design outputs – Typically the performance requirements and air emission limit the thermal oxidizer must be achieved.

“The Three T’s” of Combustion.

These are required in order to achieve successful thermal oxidation:

- Turbulence – Thorough mixing

- Temperature – Oxidizing temperature (typically 1200°F – 1650°F)

- Time – Combustion chamber residence time (typically 0.5 seconds – 2.0 seconds)

The Three T’s of Combustion, along with sufficient oxygen, are essential and interrelated in all thermal oxidizer designs. The level of turbulence (mixing), the necessary reaction temperature, and the amount of time (residence time) is primarily dependent on the waste stream characteristics and the level of destruction required for achieving the specific air permit compliance.

PCC custom designs all of our thermal oxidizer systems. Our extensive industrial application experience coupled with our experience in handling a wide spectrum of waste streams, give us the expertise to determine how best to incorporate the Three T’s of Combustion into each thermal oxidizer design.

Step 3

Determine essential design features.

As we mentioned, a basic thermal oxidizer system includes a refractory system, burner, exhaust stack, and combustion controls. More complex thermal oxidizer systems include heat recovery such as gas to gas heat exchangers and waste heat boilers, plus additional downstream pollution control equipment such as scrubbers, particulate filters, and wet ESP’s. Each of these components has a variety of important design features (too extensive to discuss here), which must be considered to ensure the complete thermal oxidizer “system” is safe, reliable, and meets all performance objectives.

Other important factors to consider when evaluating a thermal oxidizer supplier:

- Experience level with the specific application

- Industry reputation

- Process design capabilities

- In-house expertise

- Project execution and delivery reputation

- Services (installation, start-up, training, routine maintenance, etc.)

- Financial strength

Step 4

Learn more.

Discover why PCC is the right choice for your next thermal oxidizer system. Contact us directly at (412) 655-0955, or complete our Thermal Oxidizer Inquiry form and return to us for pricing and information.

What is an industrial waste incinerator?

Any device or system that uses combustion and/or thermal oxidation to destroy or reduce an industrial waste can be classified as an industrial waste incinerator. Most commercial, industrial, municipal and institutional wastes are classified by composition and heating value.

In 1968, the Incinerator Institute of America used general classifications to define waste streams. While these classifications are broad and somewhat outdated (the definition and composition of these waste streams have changed with advances in technology, products and services), they still serve as a reference for industrial waste incinerators.

Waste classifications defined.

Type 0 Waste – Trash consisting of highly combustible waste paper, wood, cardboard cartons and including up to 10% treated papers, plastic or rubber scraps from commercial and industrial sources. Type 0 Waste has a heating value of 8,500 Btu per pound, a moisture content of 10% (by weight) and an ash content of 5% (by weight).

Type 1 Waste – Rubbish consisting of combustible waste paper, cartons, rags, wood scraps, combustible floor sweepings from domestic, commercial and industrial sources. Type 1 Waste is a mixture of 80% (by weight) rubbish and 20% (by weight) garbage. It has a heating value of 6,500 Btu per pound, a moisture content of 25% (by weight) and an ash content of 10% (by weight).

Type 2 Waste – Refuse (Municipal Solid Waste) consisting of rubbish and garbage from residential sources (50% rubbish and 50% garbage). Type 2 Waste has a heating value of 4,300 Btu per pound, a moisture content of 50% (by weight) and an ash content of 7% (by weight).

Type 3 Waste – Garbage consisting of animal and vegetable food wastes from restaurants, hotels, markets, institutional, commercial and club sources. Type 3 Waste is a mixture of 65% garbage and 35% rubbish. It has a heating value of 2,500 Btu per pound, a moisture content of 70% (by weight) and an ash content of 5% (by weight).

Type 4 Waste – Pathological Waste consisting of 100% animal and human tissue. The principal components are carcasses, organs, solid organic wastes from hospitals, laboratories, abattoirs, animal pounds and similar sources. Type 4 Waste has a heating value of 1,000 Btu per pound, a moisture content of 85% (by weight) and an ash content of 5% (by weight).

Type 5 Waste – Industrial process wastes including gaseous, liquid or semi-liquid wastes. The composition, heating value, moisture content and ash content of Type 5 Wastes are variable and must be confirmed by a waste analysis.

Type 6 Waste – Semi-solid and solid combustible wastes which require hearth, retort or grate burning equipment. The composition, heating value, moisture content and ash content of Type 6 Wastes are variable and must be confirmed by a waste analysis.

PCC designs, fabricates and supplies industrial waste incinerators that safely and efficiently destroy many types of gaseous and liquid wastes (type 5 wastes as outlined above).

Post-Combustion NOx Reduction… SNCR or SCR?

PCC puts our proprietary technology and combustion processes know-how to work selecting the optimum burner(s), system configuration, process design, and operating conditions to meet the specified NOx emission limits. All NOx generation methods – “thermal NOx formation”, “chemical NOx formation” and “prompt NOx formation” are evaluated when determining whether low NOx burners, staged air systems, staged fuel systems and/or multi-stage combustion systems are required to achieve low NOx emissions.

What if fuel-bound nitrogen is present?

In certain situations, combustion techniques, process changes and modifying operating conditions might not meet the specified NOx emission limits. In these case, NOx emissions can be met by adding one of two post-combustion NOx reduction processes:

- Selective Non-Catalytic Reduction (SNCR)

- Selective Catalytic Reduction (SCR)

When necessary, PCC incorporates the appropriate post-combustion NOx reduction technology (SNCR or SCR) into our thermal oxidizer systems. We custom design and supply the complete SNCR or SCR package. We can also design and supply “stand-alone” SNCR or SCR systems for new or existing combustion systems.

Here is what PCC’s typical scope of supply includes:

SNCR

SCR

Table 1 – Comparison of Typical SNCR and SCR Systems

| Design Criteria | SNCR | SCR |

|---|---|---|

| NOx Reduction Efficiency | 40-75% | 60-90% |

| Temperature Window | 870°-1200°C (1600°-2200°F) |

165°-600°C (325°-1100°F) |

| Reactant | Ammonia or Urea | Ammonia or Urea |

| Reactor | None | Catalytic |

| Waste Disposal | None | Spent catalyst |

| Thermal Efficiency Debit | 0 – 0.3% | 0% |

| Energy Consumption | Low | High I.D. fan |

| Capital Investment Costs | Low | High |

| Plot Requirements | Minor | Major |

| Maintenance | Low | 3 to 5 years (typical catalyst life) |

| Ammonia/NOx (Molar Ratio) | 1.0 – 1.5 | 0.8 to 1.2 |

| Urea/NOx (Molar Ratio) | 0.5 – 0.75 | Not Applicable |

| Ammonia Slip | 5 to 20 ppmvd | 5 to 10 ppmvd |

| Retrofit | Easy | Difficult |

| Mechanical Draft | Not Required | Required |

Ammonia-based process details.

In this SNCR process, ammonia vapor carried by an air stream or steam is injected into the flue gas at the appropriate temperature zone, 870°-1200°C (1600°-2200°F), effecting a reduction of NOx to nitrogen and water.

The injection of ammonia into flue gas leads to a complexity of intermediate chain branching reactions. The following two simplified chemical equations summarize the overall process:

Equation 1 – 2NO + 4NH3 + 2O2 = 3N2 + 6H2O

Equation 2 – 4NH3 + 5O2 = 4NO + 6H2O

Equation 1 is the NOx reduction reaction which occurs in the 870°-1200°C (1600°-2200°F) temperature range by the injection of ammonia alone. NOx reduction effect can be enhanced down to 700°C (1300°F), by injection of hydrogen (H2 along with NH3). However, as indicated by Equation 2, the injection of NH3 into high-temperature flue gas results in increased NOx formation and is thus counterproductive.

For initial NOx levels of 200 ppmvd or less, NH3/NOx molar ratios of about 1.5 are commonly used.

Urea-based process details.

This SNCR process uses urea, CO (NH2)2 as a reducing agent. It injects an aqueous urea solution into the path of the NOx laden combustion products. The urea thermally decomposes to produce chemical species which react with NOx to form nitrogen, carbon dioxide, and water.

Equation 3 – CO (NH2)2 + 2NO + 1/2 O2 = 2N2 + CO2 + 2H2O

Equation 4 – 4NH3 + 5O2 = 4NO + 6H2O

In Equation 3, it follows that the stoichiometric molar rate of urea relative to NO in the combustion products is 0.5, since one mole of urea potentially has two moles of NH2 available to react with NO. The urea injection process for NOx control is also temperature sensitive. The urea solution, therefore, must be injected in the temperature range of 870°-1200°C (1600°-2200°F).

Factors that influence NOx reduction efficiency.

The NOx reduction efficiency of both SNCR processes depends on the following factors:

- Flue gas temperature in reaction zone

- Uniformity of flue gas temperature in the reaction zone

- Normal flue gas temperature variation with load

- Residence time

- Distribution and mixing of ammonia/urea into the flue gases

- Initial NOx concentration

- Ammonia/urea injection rate

- Heater configuration, which affects location and design of injection nozzles

SCR defined.

The selective catalytic reduction process removes nitrogen oxides (NOx) from flue gases by injecting ammonia (NH3) into the flue gas and passing the well-mixed gases through a catalyst bed. NOx reacts with NH3 in the presence of the catalyst to produce nitrogen (N2) and water (H2O) as shown in the following equations.

Equation 5 – 4NO + 4NH3 + O2 = 4N2 + 6H2O

Equation 6 – 6NO + 4NH3 = 5N2 + 6H2O

Equation 7 – 2NO2 + 4NH3 + O2 = 3N2 + 6H2O

Equation 8 – 6NO2 + 8NH3 = 7N2 + 12H2O

Equation 9 – NO + NO2 + 2NH3 = 2N2 + 3H2O

Note that the first reaction for refinery applications generally dominates since 90% of the NOx is NO. A wide variety of available catalysts can operate at flue gas temperature windows ranging from 165°–600°C (325°–1100°F). High NOx reduction efficiencies can be achieved if the parameters such as residence time, space velocity, and the correct temperature window are controlled.

The common ratio for SCR technology is NH3/ NOx molar ratio of 1.0.

What are landfill gas thermal oxidizers?

PCC has been supplying thermal oxidizers to the landfill gas industry for nearly 30 years. Over that period, we have gained the knowledge necessary to provide the most effective and well-engineered solutions to our customers.

Our thermal oxidizers can use “street grade” natural gas, raw landfill gas, and/or some of the partially processed high Btu gases derived from the customer’s process as fuel fur the burner. In some cases, heat recovery in the form of a heat exchanger is essential to provide heated streams to regenerate the media beds used in the landfill gas processing plants. Heat recovery is also added to the Thermal Oxidizer for preheating the combustion air to the burner to minimize fuel consumption.

- DRE (Destruction Rate Efficiency) up to 99.99%

- Control simplicity equals reliability

- Dual burner means reliable on-line service

- Refractory selection means long service life

- Permeate waste stream injected

- Multi Fuel options

Figure 1 – Modern Landfill Diagram

Thermal Oxidizer Advantages:

- Controlled Combustion

- Lower emissions

- Heat recovery option (Boiler, Hx)

- Adaptable to stream variations

- Durable, low maintenance

- Fuel options – NG, LFG, waste, high BTU

- High turndown with multiple burners

Call or Email to discuss your Landfill Gas needs

Flameless Thermal Oxidizers

PCC Flamesless Thermal Oxidizer (FTO) Models

“Redefining Ultra Low NOx”

Process Combustion Corporation's Flamesless Therman Oxidezer (FTO) systems are the best solution for applications that require the highest Destruction Removal Efficiencies (DRE) and lowest NOx emissions. Each FTO is fully automated and engineered to accept the full range of waste gas compositions and flow rates generated by our customer's manufacturing process.

Untouchable DRE > 99.9999%

Ultra Low NOx < 1 ppmv

Self-sustaining for Waste Gas > 10 BTU/scf

100% Waste Gas Turndown Capability

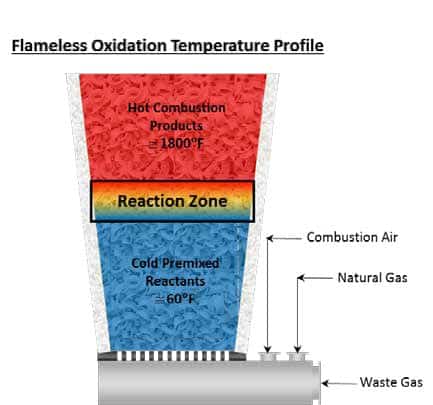

How do we achieve such low NOx?

A typical burner system can have hot spots within its flame that exceeds 3,000°F. High flame temperatures, even for short residence times (msec), can cause large amounts of Thermal NOx to be generated.

PCC's Flameless Thermal Oxidizer premixes waste gas with air and natural gas prior to treatment. The FTO's operating temperature is lower and more uniform throughout the media bed which leads to NOx generation as low as 1 ppmv.

How do we achieve 99.9999% DRE?

In any Oxidation System, destruction is determined by the Three T's:

Turbulence: Efficient or Premixing

Time: Residence Time

Temperature: >1400°F

PCC's Flameless Thermal Oxidizer achieves all three of these metrics by design.

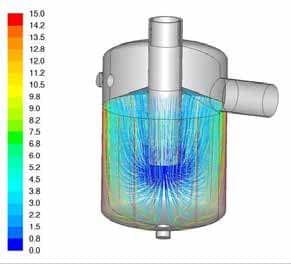

Elliptical Model Residence Time CFD Analysis

TURBULANCE

A PCC Flameless Thermal Oxidizer perfectly mixes waste gas, air, and fuel gas. This allows excess oxygen to more successfully find and react with organic material in the gas mixture once preheated to each compounds auto-ignition temperature.

TIME

The flow through a PCC Flameless Thermal Oxidizer involves multiple seconds of residence time at high temperatures. Because perfect mixing has already been achieved, high gas velocities are not required. As a result, the flow through each unit can be slower leading to longer retention times for oxidation reactions to reach completion.

TEMPERATURE

Each PCC Flameless Thermal Oxidizer operates with a completely uniform temperature profile that means the entire gas flow passes through a bed with a constant temperature profile to ensure that optimum destruction is achieved.

Competing Technologies

In a global economy with a number of potential control technologies to choose from, it is important for companies to understand their options. It is also important to recognize that environmental regulations can only get more stringent in the future. Forward thinking companies with a strong sense of corporate social responsibility want the best available control technology (BACT) at their manufacturing facilities. The figures shown below compare the performance of common control technologies for gaseous waste streams with PCC's Flameless Thermal Oxidizer.

| Project Parameter | PCC* | Thermal Oxidizer (TO)* | Carbon Adsorption Technology* | BioOxidizer* | Regenerative Thermal Oxidizer (RTO)* | Catalytic Oxidizer (CO) |

|---|---|---|---|---|---|---|

| High Concentration | X | X | ||||

| Low Concentration | X | X | X | X | X | X |

| Halogenated Service - Cl, Fl, Br | X | X | X | |||

| Sulfur, Mercaptans, thiols, etc. | X | X | X | X | ||

| DRE 99.99%+ | X | X | ||||

| NOx < 5 ppmv | X | X | X |

The PCC Flameless Thermal Oxidizer achieves 50x less NOx than the industry standard burner

Flameless Thermal Oxidizers FAQ

What is flameless oxidation?

Flameless oxidation is a thermal treatment that premixes waste gas, ambient air, and auxiliary fuel prior to passing the gaseous mixture through a preheated inert ceramic media bed. Through the transfer of heat from the media to the gaseous mixture, the organic compounds in the gas are oxidized to innocuous by-products, i.e., carbon dioxide (CO2) and water vapor (H2) while also releasing heat into the ceramic media bed.PCC’s Flameless Thermal Oxidizers are designed to operate safely and reliably below the composite LFL while also maintaining a constant system flow and temperature. Waste gas streams experience multiple seconds of residence time at high temperatures leading to measured destruction removal efficiencies that exceed 99.9999%. Premixing all of the gases prior to treatment eliminates localized high temperatures which leads to thermal NOx as low as 1 ppmv.

Why use a flameless oxidizer?

In a global economy with a number of potential control technologies to choose from, it is important for companies to understand their options. It is also important to recognize that environmental regulations can only get more stringent in the future. Forward thinking companies with a strong sense of corporate social responsibility want the best available control technology (BACT) at their manufacturing facilities. Flameless Oxidation has proven to be the best control technology for the Pharmaceutical and Specialty Chemical Industries because of each systems reliability and high emission performance. The figures show below compare the performance of common control technologies for gaseous waste streams with PCC’s Flameless Thermal Oxidizer.

What are PCC's Flameless Thermal Oxidizer (FTO) Models?

PCC offers three different types of Flameless Thermal Oxidizer models based on the volume of waste gas being

treated:

| Model | Treatment Capacity (scfm) |

| Electric FTO | 0 to 100 |

| Planar FTO | 100 to ~5,000 |

| Elliptical FTO | 750 to 100,000+ |

Electric FTO

- The electric model consists of a vertical refractory lined vessel filled with ceramic media.

- Ceramic media is preheated through the use of electric resistance heaters.

- Waste gas and ambient air are premixed at the bottomo f the unit and introduced into the unit.

- Organic compounds in waste gas are oxidized and discharged to atmosphere via a stack extension on the top of the vessel.

Planar FTO

- The Planar model is a refractory lined inverted cone vessel filled with ceramic media.

- Ceramic media is preheated through the use of a small auxiliary natural gas burner.

- Waste gas, ambient air, and natural gas enter the bottom of the vessel through a gas distributor plate.

- Heat is generated via the oxidation of natural gas and waste gas.

Elliptical FTO

- The Elliptical model is a refractory lined cylinder partially filled with ceramic media.

- Ceramic media is preheated through the use of an auxiliary natural gas burner.

- Waste gas, ambient air, and natural gas are premixed at the top of the vessel and delivered to media bed through use of a central dip-pipe.

- Heat is generated via the oxidation of natural gas and waste gas.

What are the advantages to PCC's Flameless Thermal Oxider (FTO) Models?

- Destruction Removal Efficiencies greater than 99.9999%.

- NOx emissions of less than 1 ppmv.

- Self-sustaining for fume streams as low as 10 BTU/scf

- Ceramic media bed is stable and resilient to temperature fluctuations.

- Sets the bar for BACT requirements for gaseous waste streams.

- Waste stream feed forward control ensures stability and prevents nuisance shutdowns.

How does PCC achieve such a low NOx?

A typical burner system can have hot spots within its flame that exceeds 3,000°F. High flame temperatures, even for short residence times (msec), can cause large

amounts of Thermal NOx to be generated.

PCC's Flameless Thermal Oxidizer premixes waste gas with air and natural gas prior to treatment. The FTO's

operating temperature is lower and more uniform throughout the media bed which leads to NOx generation as low as 1 ppmv.

How does PCC achieve a 99.999% DRE?

In any Oxidation System, destruction is determined by the Three T's:

- Turbulence: Efficient or Premixing

- Time: Residence Time

- Temperature: >1400°F

PCC's Flameless Thermal Oxidizer achieves all three of these metrics by design.

Turbulence

A PCC Flameless Thermal Oxidizer perfectly mixes waste gas, air, and fuel gas. This allows excess oxygen to more successfully find and react with organic

material in the gas mixture once preheated to each compounds auto-ignition temperature.

Time

The flow through a PCC Flameless Thermal Oxidizer involves multiple seconds of residence time at high

temperatures. Because perfect mixing has already been achieved, high gas velocities are not required. As a result, the flow through each unit can be slower leading to longer retention times for oxidation reactions to reach completion.

Temperature

Each PCC Flameless Thermal Oxidizer operates with a completely uniform temperature profile that means the entire gas flow passes through a bed with a constant temperature profile to ensure that optimum destruction is achieved.

Bio Oxidation

Dual-BioPhase™ Bio Oxidation: a game‐changer in pollution abatement.

Process Combustion Corporation’s (PCC) Dual-BioPhase™ system offers an innovative bio-filtration process that achieves an entirely new level of performance for biological air treatment systems.

Bio Oxidation FAQ

What is flameless oxidation?

Flameless oxidation is a thermal treatment that premixes waste gas, ambient air, and auxiliary fuel prior to passing the gaseous mixture through a preheated inert ceramic media bed. Through the transfer of heat from the media to the gaseous mixture, the organic compounds in the gas are oxidized to innocuous by-products, i.e., carbon dioxide (CO2) and water vapor (H2) while also releasing heat into the ceramic media bed.PCC’s Flameless Thermal Oxidizers are designed to operate safely and reliably below the composite LFL while also maintaining a constant system flow and temperature. Waste gas streams experience multiple seconds of residence time at high temperatures leading to measured destruction removal efficiencies that exceed 99.9999%. Premixing all of the gases prior to treatment eliminates localized high temperatures which leads to thermal NOx as low as 1 ppmv.

Why use a flameless oxidizer?

In a global economy with a number of potential control technologies to choose from, it is important for companies to understand their options. It is also important to recognize that environmental regulations can only get more stringent in the future. Forward thinking companies with a strong sense of corporate social responsibility want the best available control technology (BACT) at their manufacturing facilities. Flameless Oxidation has proven to be the best control technology for the Pharmaceutical and Specialty Chemical Industries because of each systems reliability and high emission performance. The figures show below compare the performance of common control technologies for gaseous waste streams with PCC’s Flameless Thermal Oxidizer.

What are PCC's Flameless Thermal Oxidizer (FTO) Models?

PCC offers three different types of Flameless Thermal Oxidizer models based on the volume of waste gas being

treated:

| Model | Treatment Capacity (scfm) |

| Electric FTO | 0 to 100 |

| Planar FTO | 100 to ~5,000 |

| Elliptical FTO | 750 to 100,000+ |

Electric FTO

- The electric model consists of a vertical refractory lined vessel filled with ceramic media.

- Ceramic media is preheated through the use of electric resistance heaters.

- Waste gas and ambient air are premixed at the bottomo f the unit and introduced into the unit.

- Organic compounds in waste gas are oxidized and discharged to atmosphere via a stack extension on the top of the vessel.

Planar FTO

- The Planar model is a refractory lined inverted cone vessel filled with ceramic media.

- Ceramic media is preheated through the use of a small auxiliary natural gas burner.

- Waste gas, ambient air, and natural gas enter the bottom of the vessel through a gas distributor plate.

- Heat is generated via the oxidation of natural gas and waste gas.

Elliptical FTO

- The Elliptical model is a refractory lined cylinder partially filled with ceramic media.

- Ceramic media is preheated through the use of an auxiliary natural gas burner.

- Waste gas, ambient air, and natural gas are premixed at the top of the vessel and delivered to media bed through use of a central dip-pipe.

- Heat is generated via the oxidation of natural gas and waste gas.

What are the advantages to PCC's Flameless Thermal Oxider (FTO) Models?

- Destruction Removal Efficiencies greater than 99.9999%.

- NOx emissions of less than 1 ppmv.

- Self-sustaining for fume streams as low as 10 BTU/scf

- Ceramic media bed is stable and resilient to temperature fluctuations.

- Sets the bar for BACT requirements for gaseous waste streams.

- Waste stream feed forward control ensures stability and prevents nuisance shutdowns.

How does PCC achieve such a low NOx?

A typical burner system can have hot spots within its flame that exceeds 3,000°F. High flame temperatures, even for short residence times (msec), can cause large

amounts of Thermal NOx to be generated.

PCC's Flameless Thermal Oxidizer premixes waste gas with air and natural gas prior to treatment. The FTO's

operating temperature is lower and more uniform throughout the media bed which leads to NOx generation as low as 1 ppmv.

How does PCC achieve a 99.999% DRE?

In any Oxidation System, destruction is determined by the Three T's:

- Turbulence: Efficient or Premixing

- Time: Residence Time

- Temperature: >1400°F

PCC's Flameless Thermal Oxidizer achieves all three of these metrics by design.

Turbulence

A PCC Flameless Thermal Oxidizer perfectly mixes waste gas, air, and fuel gas. This allows excess oxygen to more successfully find and react with organic

material in the gas mixture once preheated to each compounds auto-ignition temperature.

Time

The flow through a PCC Flameless Thermal Oxidizer involves multiple seconds of residence time at high

temperatures. Because perfect mixing has already been achieved, high gas velocities are not required. As a result, the flow through each unit can be slower leading to longer retention times for oxidation reactions to reach completion.

Temperature

Each PCC Flameless Thermal Oxidizer operates with a completely uniform temperature profile that means the entire gas flow passes through a bed with a constant temperature profile to ensure that optimum destruction is achieved.